Steels

3 types of steel are used to ensure that a client’s needs are best suited.

The 80crV2 (1.2235): This is a tough steel suitable for large knives likely to undergo high stress (e.g. camp knife, bushcraft knife, outdoor knife, bowie knife etc.)

The 115W8 (1.2442): Comprising 1.15% carbon and 2% tungsten this is ideal for very thin and long-lasting cutting edges and for knives where the sharpness of cut is most important (kitchen knives, small fixed blades, skinners and folding knives)

The 14c28N: A stainless steel made by Sandvik. This steel offers very good resistance to corrosion and yet remains particularly easy to re-sharpen. It accepts a very keen cutting edge and is perfectly suited to all types of small knives as well as kitchen knives.

Heat treatments

Great importance is placed on heat treatments. Numerous tests are undertaken for each type of knife according to its purpose.

Heat treatments are carried out by way of specialist high quality tools (heat treating furnace, quenching oil, heat treat foil, aluminium quench plates etc.). Each type of steel is treated by its own process and according to the end use to which the knife is to be put.

Very close attention to detail is paid to this operational stage, which is essential for producing a high quality knife. These techniques ensure that the optimum quality of the chosen steel is achieved.

Materials for the handle

A wide selection is possible. The materials chosen will vary according to the aesthetic style and end use of the knife.

These can be synthetic (e.g. micarta, G10) or natural (wood, horn, bone etc.)

Synthetic materials are extremely resistant, solid and completely rotproof. It is the perfect choice for knives liable to be affected by humid conditions and where cleaning and maintenance can be done easily (marine knife, kitchen knife, hunting knife etc.)

Natural materials offer a warm feel and appealing look. They will mature with age over the years. Depending upon the type chosen, occasional cleaning and maintenance may be necessary.

Sheaths

Sheaths can be produced in leather or kydex. Both materials present a number of advantages.

Kydex affords great resistance to wear over time. It is 100% rotproof and cleans very easily. These sheaths are slim and light, provide excellent retention, are secure and can be carried in many different ways. Prices are less than leather sheaths.

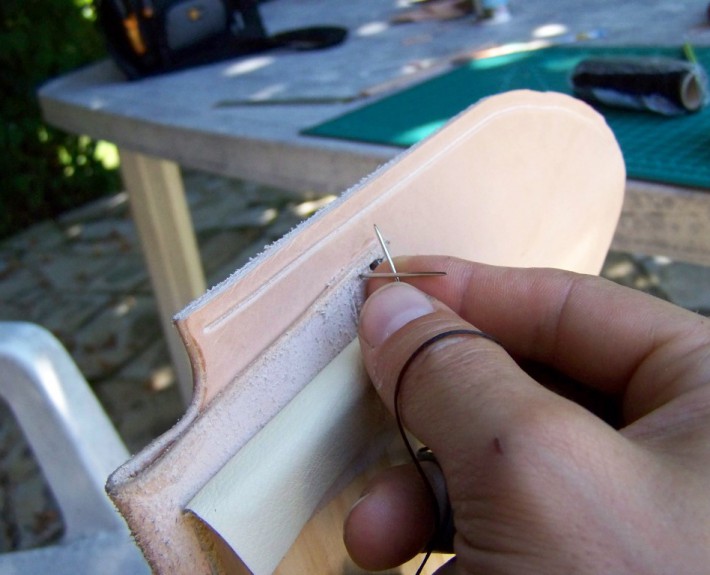

Leather is a natural and high value material suitable for producing sheaths with excellent hold characteristics (wet molded leather) and with many alternative ways of carrying them. Working with leather provides scope in form and colour to enable really stylish and personalised sheaths to be made.